Ultimate Guide To The Best Fabric Scanners (2025)

- Victoria Pi

Table of Contents

How Fabric Scanners and Digital Materials Are Reshaping Sustainable Fashion Design

The Sustainability Crisis in Fashion

The fashion industry stands at a critical crossroads. Responsible for 20% of global wastewater and generating a staggering 92 million tonnes of textile waste annually, the industry faces mounting pressure to seek sustainable alternatives. The environmental cost of traditional fashion production is unsustainable, with physical sampling alone contributing significantly to this waste.

Emerging technologies like generative AI, virtual reality, 3D design, and augmented reality present transformative opportunities. These innovations create pathways to more sustainable design and production processes.

The Digital Materials Shift

Digital materials represent virtual replicas of physical textiles that can be manipulated, tested, and implemented in 3D design environments. As these digital assets become central to sustainable practices, the demand for high-quality material digitization solutions is surging across the industry.

The shift is driven by widespread adoption of Digital Product Creation (DPC) workflows. According to the Interline DPC Report 2024, DPC is evolving from a niche innovation into a cross-functional enabler of end-to-end product development. From concept and design to merchandising and marketing, DPC reduces physical sampling needs and speeds up development. Leading brands utilize DPC to unlock new levels of collaboration, creativity, and digital readiness across the organization.

This digital transformation extends beyond production efficiency. Brands are discovering new “phygital” (physical and digital) experiences for customer engagement. For example, Gucci generated over $1 million by selling 100,000 digital items in the metaverse, demonstrating the substantial commercial potential of digital fashion beyond sustainability benefits.

What is a Fabric Scanner?

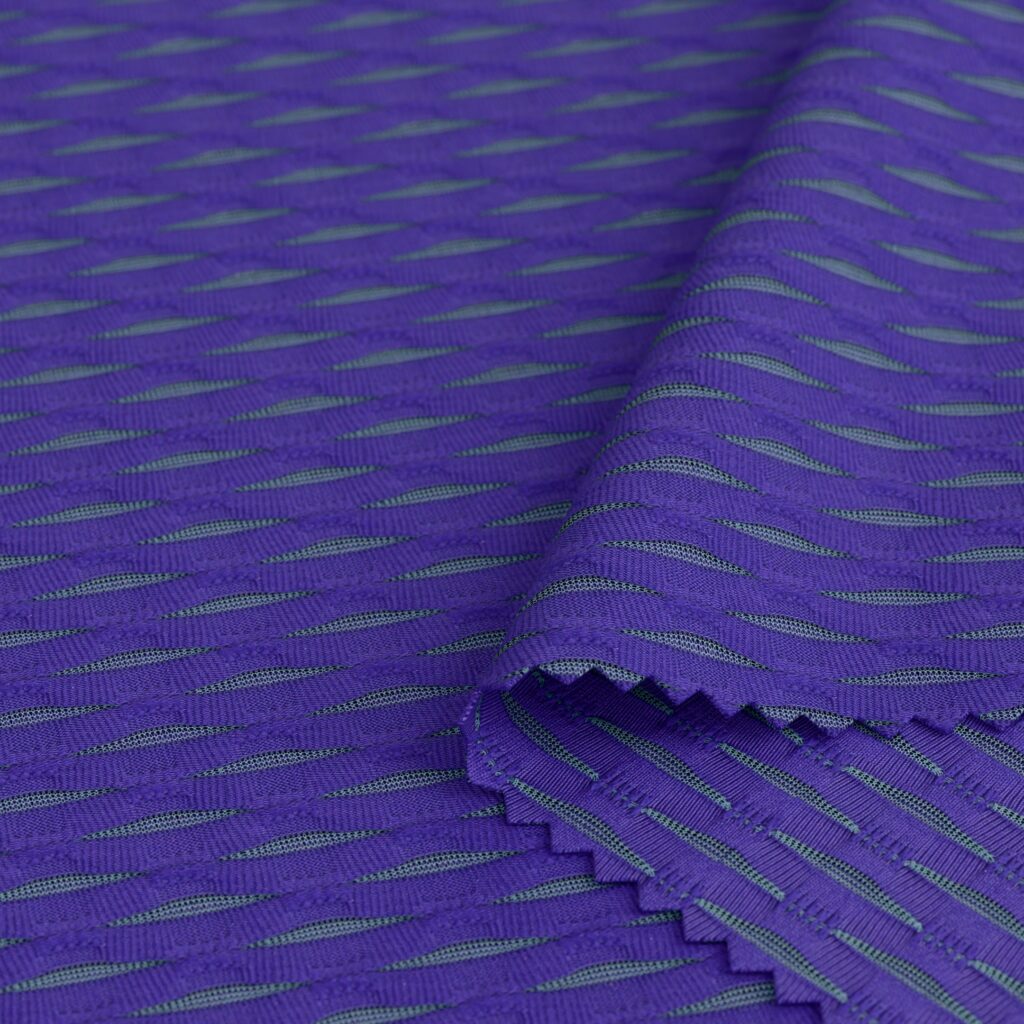

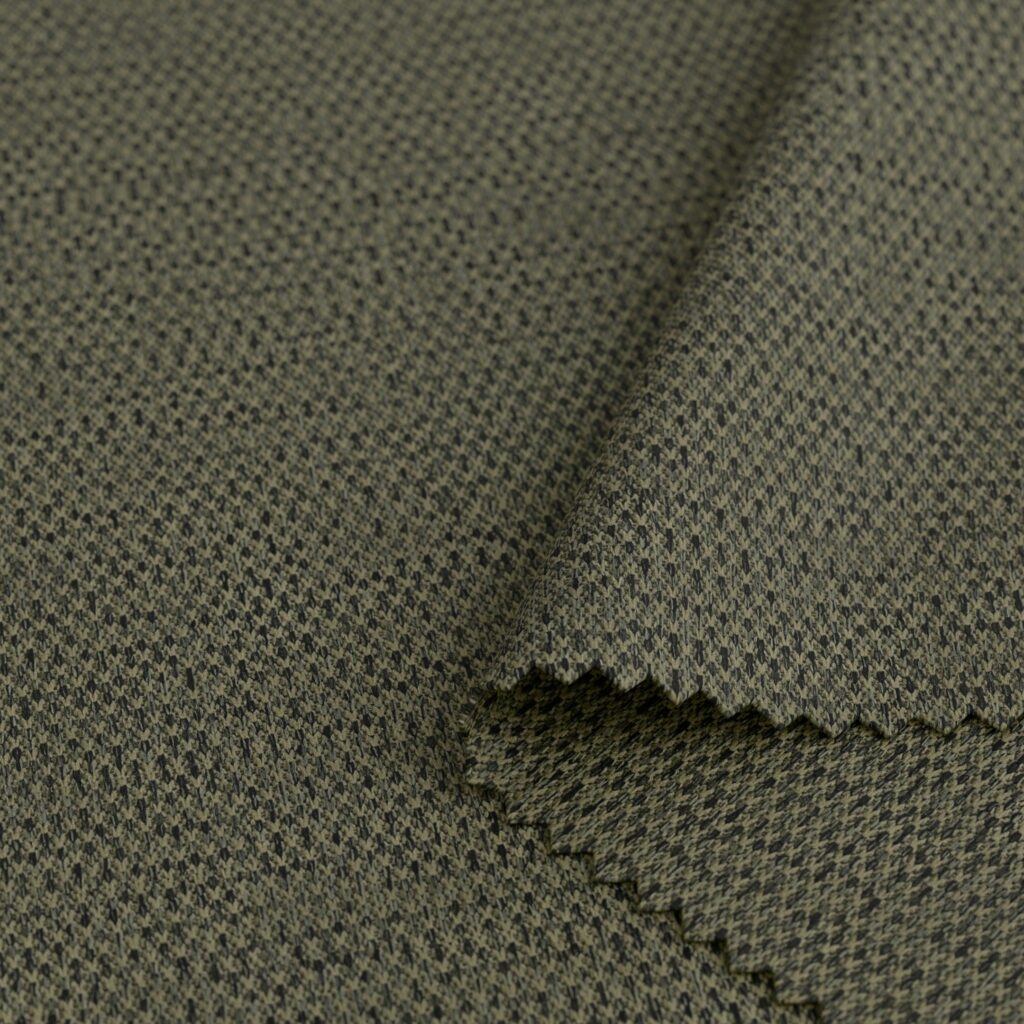

Fabric scanners are specialized devices that capture the physical details of materials (e.g., texture, pattern, color, and structure) to create high-quality digital representations or “digital twins.” These scanners bridge the gap between physical textiles and digital product creation workflows.

Modern fabric scanners typically combine high-resolution cameras with uniform lighting systems to eliminate shadows and glare, ensuring accurate color representation. The captured data generates comprehensive texture maps that allow computers to visualize materials in 3D with remarkable fidelity to their physical counterparts.

Digital material assets enable rapid iterations and optimizations of product designs. Adjustments can be made in real-time, dramatically reducing the need for physical tests and sample cycles before production.

The Growing Importance of Fabric Scanners In 2025

Fabric scanners significantly reduce physical sampling needs by allowing designers to visualize fabric properties in 3D environments. This enables experimentation with different colors, textures, and patterns before committing to samples or prototypes. The resulting digital design flexibility allows brands to respond rapidly to market trends.

The sustainability benefits are equally compelling. Fewer sampling rounds mean reduced material waste, lower transportation costs, and a smaller carbon footprint. This alignment with global sustainability goals makes fabric scanners essential components in creating more efficient, innovative, and eco-friendly production workflows.

The demand for fabric scanners continues to accelerate as textile-related industries (e.g., apparel, footwear, accessories, home furnishings, and automotive) increasingly adopt digital workflows.

This growth is driven by several converging factors:

- Digital advancement initiatives: Big brands are investing heavily in digital capabilities. Many brands already have qualified technology suppliers as part of their digital creation ecosystem.

- Sustainability mandates: Regulatory pressure and consumer expectations are pushing companies to reduce waste and carbon footprints.

- Cost optimization: Economic uncertainties are accelerating the adoption of technologies that reduce expenses and improve efficiency.

- Remote work adaptations: Distributed design teams require digital assets for effective collaboration.

7 Considerations When Looking For A Fabric Scanner

Before investing in a fabric scanner, clarify your selection criteria based on your specific digital material needs.

1. Texture Map Output Quality

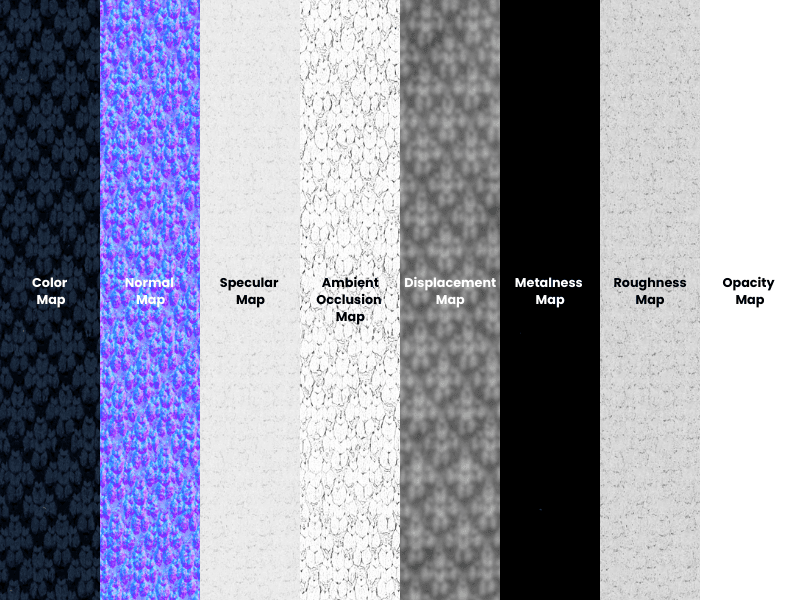

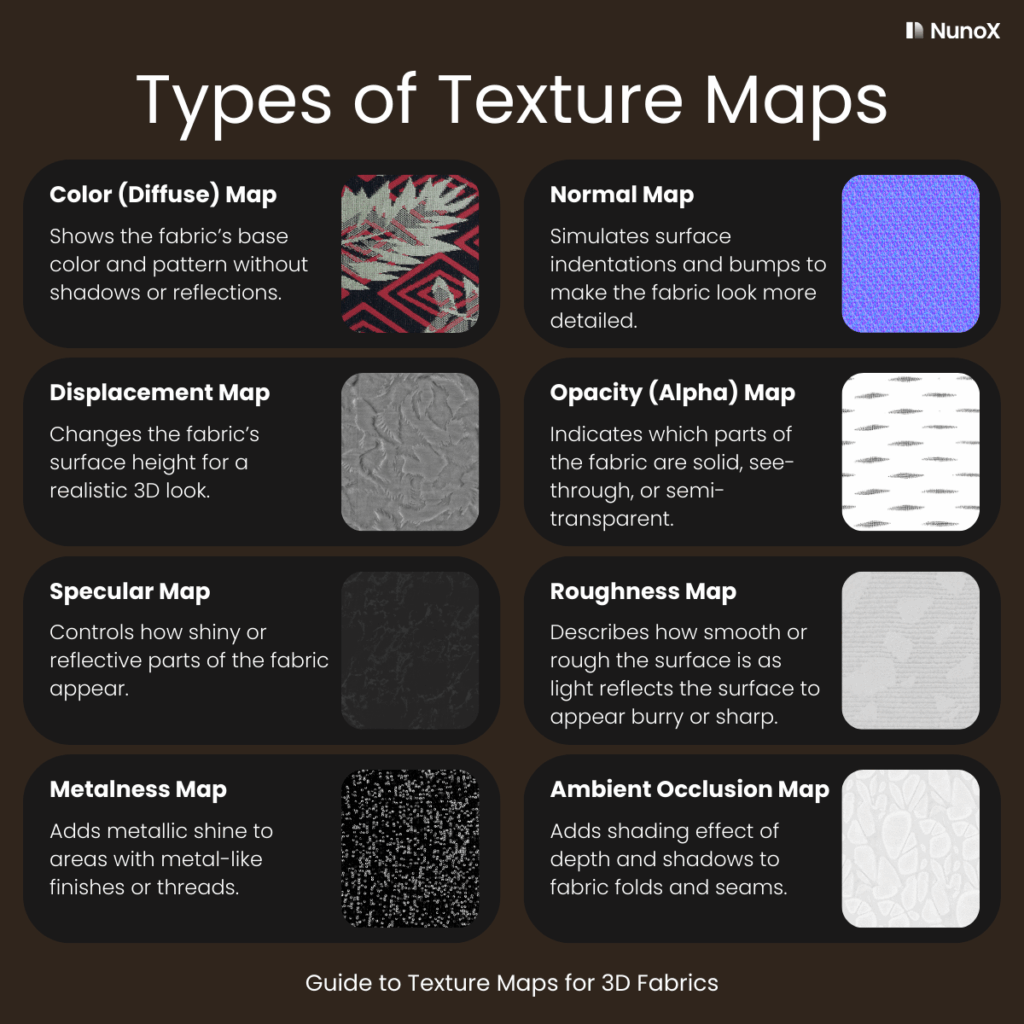

Texture maps contain detailed information about a fabric’s surface characteristics to create realistic 3D renderings. These maps play a crucial role in Physically Based Rendering (PBR) by accurately simulating how light interacts with materials in digital environments.

High-quality scanners produce several specialized maps:

- Color (Diffuse) Map: Defines a fabric’s base color and pattern.

- Normal Map: Creates the illusion of depth by simulating small bumps, indentations, and raised details without physically altering the 3D model.

- Displacement Map: Modifies the surface geometry of a 3D fabric to replicate the true feel of textures by adding real depth and structure.

- Opacity (Alpha) Map: Manages fabric transparency, determining which areas should appear solid, semi-transparent, or fully see-through.

- Specular Map: Determines the reflectivity of fabrics, controlling which areas should appear highly shiny and which should remain matte.

- Roughness Map: Controls how light scatters across a material’s surface, affecting whether a fabric appears soft and smooth or coarse and rough.

- Metalness Map: Enhances metallic threads, embellishments, and finishes in fabrics, adding a reflective quality to materials that require specialized sheen.

- Ambient Occlusion Map: Enhances natural shadows in fabric folds, creases, and seams, adding depth and contour to digital garments.

Tip: Before purchasing, request sample scans of your specific materials to evaluate texture map quality. Pay particular attention to how well the scanner captures subtle details like weave structures and surface variations.

2. Tiling & Editing Capabilities

Seamless tiling is essential for creating large digital swatches from limited scan areas. Most scanners include software with post-scan editing tools that significantly impact workflow efficiency.

Choose a scanner with robust editing features that complement your existing workflow. The right software enhances scan value by providing greater flexibility and control over the final digital materials.

Key features to evaluate include:

- Automated tiling: Check how quickly the software can create seamless tiles.

- Color adjustment tools: Confirm color matching and correction capabilities.

- Texture map export options: Ensure compatibility with your design software.

- PBR parameter controls: Look for tools to fine-tune material appearance.

3. Scan Resolution and Image Quality

Scan quality fundamentally depends on DPI (dots per inch), with higher settings capturing finer fabric details.

DPI output varies by capture technology, with most 3D fabric scanners using specialized DSLR cameras or smartphone technology. Select a resolution range aligned with your specific needs from quick iterations to final production assets.

Typical fabric scans range from 300 to 1,200 DPI, with important considerations:

- Higher DPI (600–1200): Captures exceptional detail but produces larger files requiring more storage and processing power.

- Lower DPI (300–600): Offers a practical balance between detail and file manageability, ideal for collaborative workflows.

4. Technical Support and Training

Reliable customer support and comprehensive warranties can prevent costly interruptions to your digital workflow. Responsive service ensures quick resolution of technical issues and provides guidance on scanner optimization.

Before purchasing, ask about:

- Support availability: Hours, response times, and communication channels.

- Warranty coverage: Duration and included components.

- Training resources: Documentation, videos, and personalized onboarding.

- User community: Access to knowledge bases and peer support.

5. Ease of Use

A user-friendly scanner with an intuitive interface ensures seamless integration into existing design processes. Look for features that streamline operations, such as batch scanning capabilities, straightforward file management, and automated calibration.

The ease of use often becomes a deciding factor, particularly in environments where multiple team members with varying technical expertise will operate the scanner.

Consider the learning curve and evaluate:

- Interface design: Clarity and accessibility of controls.

- Automation features: Batch processing and preset capabilities.

- Setup complexity: Time required for calibration and preparation.

- Workflow compatibility: Alignment with existing processes.

6. Pricing

Scanner pricing varies widely based on features and capabilities. Some manufacturers offer hardware-software bundles, while others sell components separately. Understanding the total investment required helps ensure alignment with your budget and expected returns.

More expensive systems typically include advanced features and greater customization capabilities, making them suitable for larger enterprises with specific requirements.

Budget-friendly options exist for small businesses or individual designers who need reliable scanning without excessive investment.

When evaluating pricing, look for transparency regarding what’s included. Clarify terms for software updates, maintenance services, and ongoing support to avoid unexpected costs.

Key cost factors include:

- Initial hardware investment: Scanner equipment and accessories.

- Software licensing: One-time purchase or subscription models.

- Maintenance requirements: Regular calibration and component replacement.

- Training expenses: Onboarding and continuous education costs.

7. Software Integration

Most design teams already use established 3D design tools. Successful scanner implementation depends on seamless integration with this existing software ecosystem.

Verify compatibility with popular platforms such as CLO3D, Browzwear, and Adobe Suite. Check support for industry-standard file formats like U3M, JPEG, or PNG to ensure smooth transfer between systems.

Proper integration means incorporating digital fabrics into existing processes without disrupting established workflows.

NunoX Premium Scanner

ColorMass Scanner

DMix SampIR

Vizoo xTex Scanner

Top 4 Fabric Scanners 2025

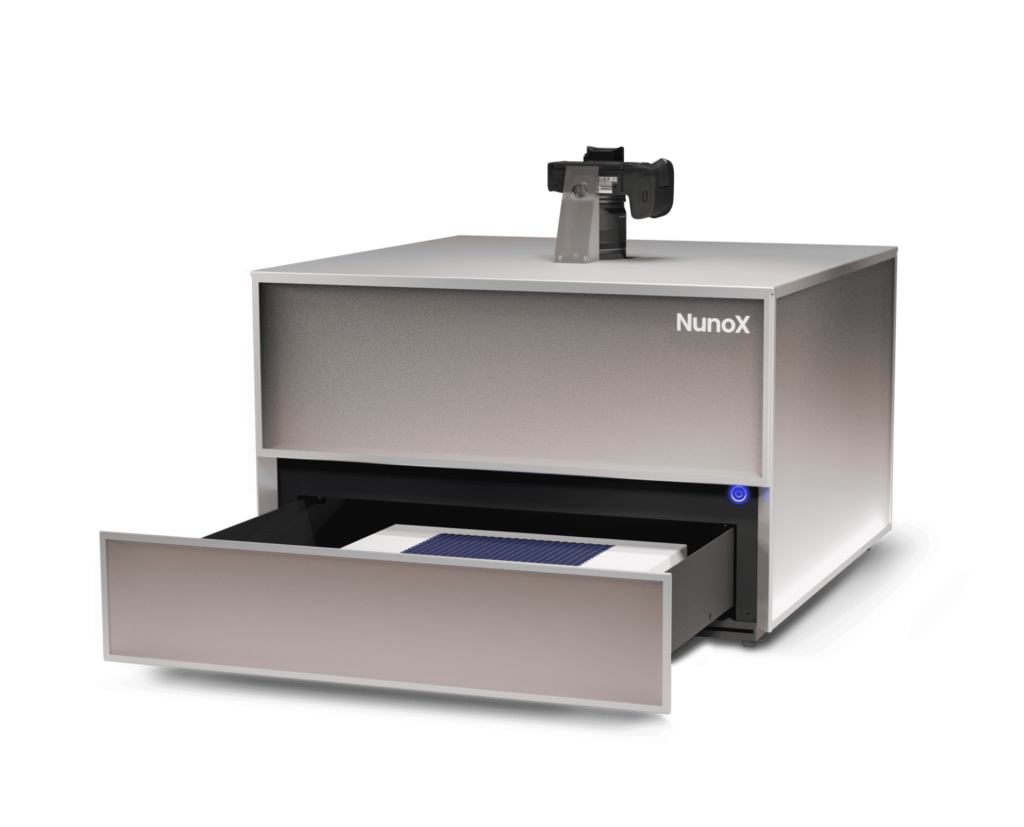

NunoX Premium Scanner

NunoX specializes in integrating AI with 3D scanning technology to create high-quality digital twins of materials. The NunoX Premium Scanner, combined with its cloud-based software, simplifies the process of material digitization through advanced AI features. This asynchronous workflow supports batch scanning and separate tile editing, providing flexibility and efficiency.

The NunoX Cloud platform is accessible via popular web browsers, facilitating global collaboration. Key AI-powered features include texture map generation, automatic tiling, and fabric physics simulation.

Products:

- NunoX Premium Scanner: High-resolution material capture using the Canon EOS R5 camera.

- NX Suite: Cloud-based material editor with AI features including auto-tiling, fabric drape simulation, and texture map generation.

Colormass Scanner

Berlin-based colormass offers a comprehensive 3D infrastructure solution focused on material digitization and content management. Colormass’s cloud-based platform centralizes 3D assets for different use cases, including rendering images for marketing, creating materials, and exporting data for distribution.

Products:

- 4th Generation PBR Material Scanner: Capture large material surfaces in high detail without visible tiling.

- Tiling Editor: An AI-powered solution for tiling and post processing scans.

- Content Management System: Cloud-based system for organizing and updating 3D product content with flexible logic controls.

- 3D Configurator: Configure product specifications and generate AR models automatically.

- Rendering Platform: Edit and render 3D scenes from your browser.

- Data Exporter: Pull data from 3D models for use in other systems or workflows.

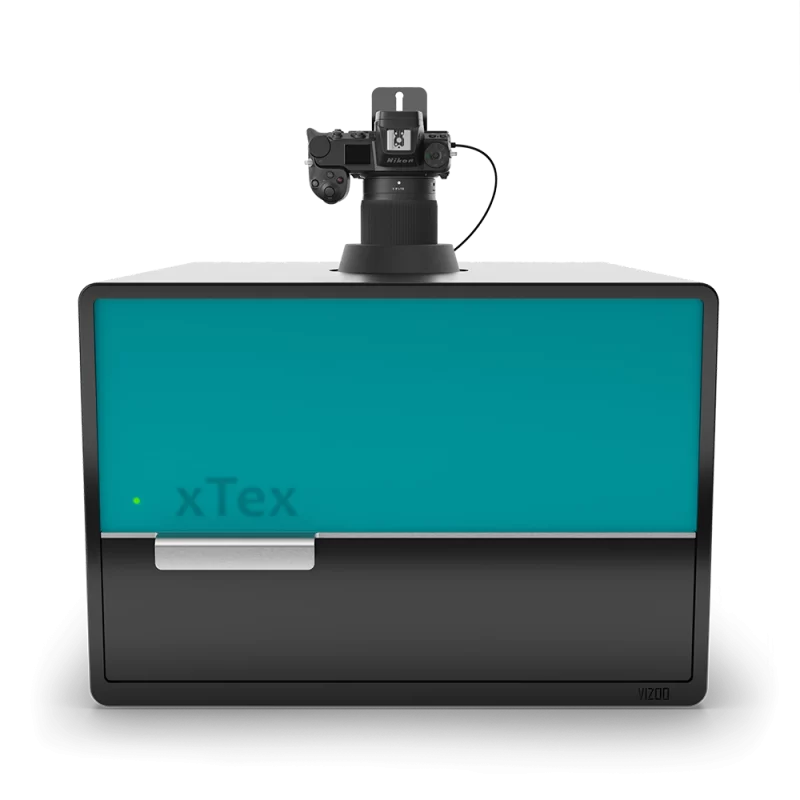

Vizoo xTex Scanner

Founded in 2013 in Germany, Vizoo focuses on high-resolution 3D scanning and texture creation. Their flagship xTex Scanner captures exceptionally detailed digital representations of fabrics.

Products:

- xTex Scanner: High-resolution material capture using Nikon’s Z7 camera series.

- xTex Software: Comprehensive material editor for tiling, recoloring, and exporting texture maps.

- PhysX Platform: Database providing physical parameters for 3D garment simulation.

- Cast: See fabrics on 3D products instantly with real-time fabric streaming.

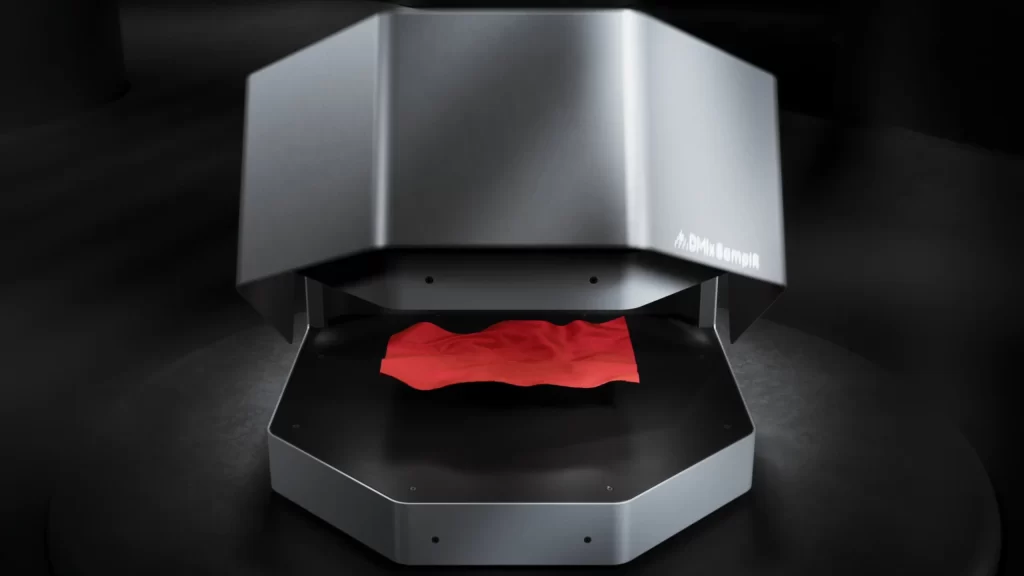

DMix SampIR Scanner

The DMIx SamplR scanner, developed by ColorDigital GmbH in Germany, leverages iPhone camera technology to create digital material twins. One of its standout features is the ability to provide behavior videos of samples.

DMix offers a comprehensive digital ecosystem combining color management, 3D technology, and material digitization.

-

Products:

- SampIR: One-button material capture tool using the iPhone 15 camera.

- 3D Technology: Cloud-based platform with tools for digitizing, editing, and sharing 3D materials and products.

- Color Technology: Digital color management system that utilizes spectral measurements to ensure precise color evaluation.

Comparison Table

| Brand | NunoX | colormass | Vizoo | DMIx |

|---|---|---|---|---|

| Scanner Hardware | NunoX Premium Scanner | colormass Scanner | xTex Scanner Hardware | SampIR |

| Software | NX Suite | colormass Platform | xTex Software | DMix Platform |

| Scan Area | A4 (30 x 20 cm) | 1.8m x 1.8m (customizable) | A4, A2 | ~A4 (30 x 22.5 cm) |

| Resolution | 700 dpi | 800 dpi | A4: 630–950 dpi A2: 340–720 dpi |

330 dpi |

| Capture Time | 30 seconds | 5 minutes (up to 36 samples at once) | 1–3 minutes | – |

| Capture Technology | Canon EOS R5 | Industrial camera | Nikon D850, Z7 series (45MP) | iPhone 15 / 15 Plus |

| Hardware Size | 60 x 60 x 50 cm | Custom-built on-site | A4: 48 x 58 x 36 cm A2: 92.5 x 93.3 x 166.3 cm |

50 x 50 x 25 cm |

| PBR Texture Maps | Yes | Yes | Yes | Yes |

| File Output Formats | U3M, U3MA, JPG, PNG | JPG, TIFF, PNG, EXR | U3M, U3MA, xTex, SBS, SBSAR, MDL, JPG, PNG, TIFF | GLTF, PNG |

| 3D Software Compatibility | Browzwear, CLO3D, APIs | Render engine optimized | Browzwear, CLO3D, APIs | CLO3D, Adobe Substance, APIs |

| Specialization | AI tools | svBRDF capture, high throughput, AI tiling | Comprehensive texture capture | Color management |

| OS Compatibility | Mac OS, Windows | Mac OS, Windows | Windows | Mac OS, Windows |

| Video Capabilities | No | No | No | 4K / 60 FPS |

How Digital Materials Are Advancing Fashion Design

1. Searchable Digital Material Libraries

Build a comprehensive digital fabric library to organize and access all material assets. Quickly locate fabric details and inventory information without needing physical samples on hand. Sort and filter by characteristics such as color, brand, and material type to support better decision-making.

2. Reduce Physical Sampling Costs

Save time and money on physical sampling rounds with digital fabrics. With mounting costs for material, labor, shipping, and time delays, digital fabric twins can significantly reduce these expenses.

Beyond cost savings, this approach minimizes environmental impact by reducing textile waste and transportation carbon emissions. Resources previously allocated to sampling can be redirected to team upskilling in digital capabilities, creating a virtuous cycle of innovation.

3. Accelerate Product Development

The traditional product development cycle in fashion can stretch anywhere from 6-18 months. Digital materials enable rapid prototyping and iterative design, potentially reducing this timeline. Designers gain creative freedom, making quick adjustments and exploring more diverse collections without the constraints of physical sampling cycles.

This acceleration is critical in an industry where market responsiveness determines success. Brands can test concepts quickly, gather feedback, and pivot designs before committing to production.

4. Enhance Visual Marketing Content

Digital materials enable the creation of photorealistic 3D renderings for product visualization without expensive photoshoots. These high-quality visuals can populate e-commerce platforms, social media, advertisements, and other promotional channels to showcase product features with remarkable accuracy.

Brands can now create complete digital catalogs before physical products exist, allowing pre-orders and market testing with minimal investment. This approach also supports sustainability messaging by highlighting the reduced environmental footprint of digital-first design processes.

5. Seamless Global Collaboration

Digital fabrics enhance collaboration across dispersed teams. Designers, manufacturers, and clients can share and review digital assets instantly, enabling real-time feedback regardless of location. This global accessibility accelerates approval processes, speeds up project timelines, and democratizes design participation.

Material Digitization is the Future of Textiles

Sustainability and innovation go hand-in-hand to solve the fashion industry’s pressing challenges. Integrating fabric scanners to create digital materials offers a potential solution to many of the industry’s pressing challenges, from reducing waste to accelerating design processes.

By digitizing physical fabrics, designers and manufacturers can explore new creative possibilities, streamline production, and contribute to a more sustainable future. As the demand for efficiency and eco-friendly practices grows, embracing these digital tools is necessary for staying competitive in the evolving market. Explore the latest fabric scanning technologies, and begin building your digital assets to be ready for the technological future of fashion.

Share the Post: